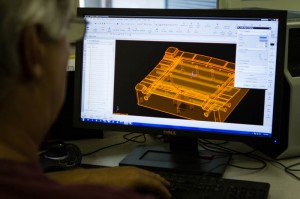

Superior products start with superior design. Our design process for creating superior plastic injection molding tools starts with great communication with our client and continuous attention on market developments in the global plastics industry. Once we receive specifications and electronic data files for a plastic part order, we are off to design a quality mold that will exceed our customers’ expectations.

Superior products start with superior design. Our design process for creating superior plastic injection molding tools starts with great communication with our client and continuous attention on market developments in the global plastics industry. Once we receive specifications and electronic data files for a plastic part order, we are off to design a quality mold that will exceed our customers’ expectations.

In plastic injection molding, plastic pellets are heated at a high temperature to turn the plastic into fluid. The viscous plastic fluid is then forced into the mold cavity or cavities under high pressure. Once filled, the newly molded part is cooled and ejected from the mold.

The mechanical properties of plastic resins are often difficult to quantify; tolerances are getting tighter as technology improves; and we all know economics play an important role. Molds need to hold up to the demands of production. Many of our molds are designed to produce over a million cycles during the life of the mold.

It is in the engineering design process that we identify potential problems with manufacturing the part. We put the design through a rigorous formal process calledDesign for Manufacturability (DFM).

It is in the engineering design process that we identify potential problems with manufacturing the part. We put the design through a rigorous formal process calledDesign for Manufacturability (DFM).

It is during this process that problems are identified with gating, cooling, shut off angles, along with the overall manufacturability of a part. Our skilled engineers will identify issues with non-uniform deformation and expansion of mold components that will be experienced during the injection molding process. We identify the best location for the parting lines and ejector pins. This is especially important when cosmetics are critical and must be positioned in non-visible areas of the part.

During a tool’s lifetime it may produce over a million cycles. In addition to reducing potential molding issues we pay a lot of attention to reducing mold cycle times. Shaving a few seconds of time from a molding cycle can dramatically impact profits for a client.

We focus on developing deep relationships we our injection molding manufacturers. Our customers consistently praise us for our excellent communication of project progress, at all points. We identify potential problems quickly and report any delays immediately.

We focus on developing deep relationships we our injection molding manufacturers. Our customers consistently praise us for our excellent communication of project progress, at all points. We identify potential problems quickly and report any delays immediately.

Our efficiency in getting the mold correct the first time gets our customers into production faster. In 98% of projects, our molds are ready for production following the first sampling.

Diamond Tool & Engineering spends the time it takes upfront to design & engineer an injection mold that has the highest level of integrity and quality.

Our expertise and attention to detail ensure you receive a tool that will hold up and reliably produce parts throughout the life of the mold. We excel at perfection because we spend the time it takes upfront to design and engineer an injection mold that is of the highest level of integrity and quality.